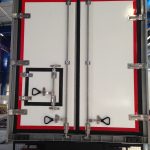

GRP BOXES

These boxes are manufactured with GRP skins externally and internally making the boxes lightweight and ensure maximum payload to customers. With sufficient reinforcements inside the sandwich panels, these boxes are well suited for heavy duty applications. The GRP material is imported from leading manufacturers in Germany. GRP used by Sub Zero always comes with a UV resistant gel coat. GRP is HAACP compliant material and is food safe. GRP offers much better insulation properties compared to steel.

Sub Zero Reefers introduces its premier line of GRP (Glass Reinforced Plastic) boxes, setting a new standard in the transport and logistics industry. Our innovative boxes are crafted with both external and internal GRP skins, combining lightweight design with the durability needed for heavy-duty applications. Sourced from leading manufacturers in Germany, the GRP material used in our boxes is not just of superior quality but also enhances the efficiency and safety of cargo transport.

One of the standout benefits of our GRP boxes is their ability to maximize payload. The lightweight nature of GRP allows for the transportation of more goods within the same weight limits compared to traditional materials. This is particularly advantageous for businesses looking to optimize their logistics operations, reduce fuel consumption, and increase their overall transport efficiency.

The GRP material is coated with a UV-resistant gel, ensuring that the boxes are safeguarded against the harsh effects of sunlight. This protective layer maintains the integrity of the boxes, extending their lifespan and preserving their appearance. Moreover, GRP’s resistance to UV radiation prevents the degradation of the material, ensuring that the boxes remain robust and reliable over time.

Our GRP boxes are constructed from a single piece of GRP, providing unparalleled strength and eliminating weak points often found in assembled units. The internal reinforcements within the sandwich panels further enhance their suitability for heavy-duty applications, ensuring that our boxes can withstand the demands of rigorous transport conditions.

Beyond their functional advantages, Sub Zero’s GRP boxes are designed with aesthetics in mind. Their sleek and modern appearance not only enhances the visual appeal of the transport units but also provides an excellent canvas for branding. The smooth surface of the GRP material is ideal for custom graphics and logos, allowing businesses to leverage their logistics operations as a mobile marketing tool.

Moreover, GRP’s superior insulation properties compared to steel make our boxes an ideal choice for temperature-sensitive cargo, ensuring products are transported in optimal conditions. Combined with the fact that GRP is HACCP-compliant and food-safe, GRP boxes are not just a logistical solution but also a commitment to quality and safety.

Our Steel boxes represent a fusion of innovation, efficiency, and safety. With their lightweight design, UV resistance, strength, and aesthetic appeal, our boxes offer a comprehensive solution for businesses seeking to enhance their logistics operations while promoting their brand on the move. Our commitment to using high-quality, food-safe GRP ensures that our boxes are not only practical but also comply with the highest standards of cargo transport.

Why GRP boxes?

- Light weight boxes maximizing payload

- GRP comes with a UV resistant gel coat

- Single piece GRP provides strength

- Aesthetically pleasing and good for branding