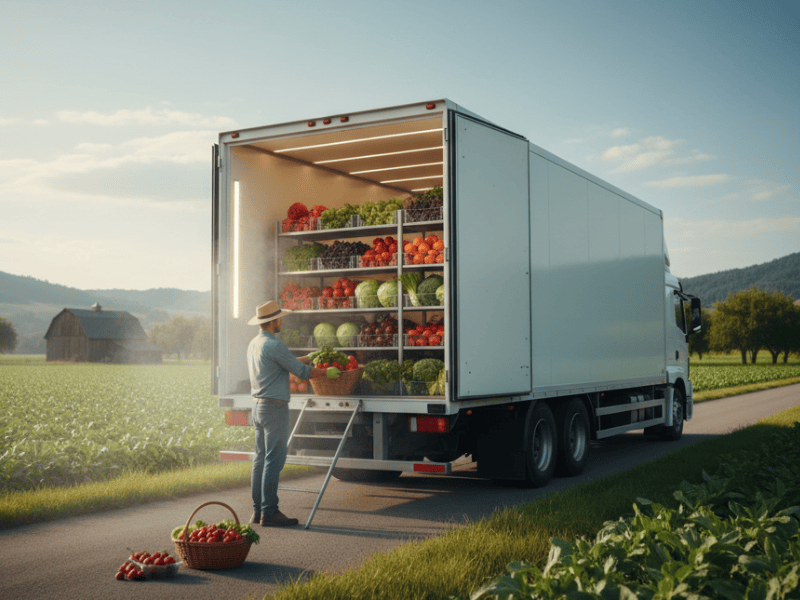

The journey from farm to table is more intricate than it appears. Once harvested, fruits and vegetables start losing freshness, flavor, and nutrients. For businesses handling vegetables transport, fruit transport, and fruit and vegetable transportation, keeping produce fresh is essential for both quality and profitability.

This is where fresh produce trucks make a difference. Modern mobile fresh produce trucks maintain precise temperatures, controlled airflow, and optimal humidity to ensure delicate items like strawberries, grapes, and avocados arrive in perfect condition. Even banana transport, watermelon transportation, and the transportation of oranges require careful temperature control to avoid premature ripening or spoilage.

Each type of produce has unique needs. For example, knowing the best way to transport bananas helps prevent over-ripening, while the best way to transport tomatoes avoids bruising and spoilage. With proper handling, packaging, and refrigeration, businesses can minimize post-harvest losses, maintain quality, and deliver produce that feels truly farm-fresh to consumers.

The Importance of Temperature Control

Temperature is arguably the most critical factor in fruit and vegetable transportation. Even slight deviations from the recommended temperature can accelerate ripening, spoilage, or the growth of harmful bacteria. A controlled environment inside refrigerated trucks ensures that delicate items such as strawberries, tomatoes, or grapes maintain their firmness, color, and flavor during transit.

Effects of Heat on Fruits & Vegetables

Heat is the silent enemy of fresh produce. For instance, banana transport requires careful temperature management, as elevated temperatures can cause bananas to ripen too quickly, develop brown spots, and lose shelf life. Similarly, strawberry transportation demands extremely precise cooling — any warmth can soften the fruit, lead to fermentation, or trigger mold growth.

Grape transportation is highly sensitive to heat. Excessive temperatures can cause shriveling and loss of juice content, impacting taste and market value. Watermelon transportation also needs low, stable temperatures to preserve texture and sweetness.

In vegetables transport, leafy greens like lettuce and spinach are highly perishable and can wilt or decay if not kept cold. Bulk items like tomatoes require the best way to transport tomatoes to avoid bruising or premature ripening. Knowing the ideal temperature for each type of produce ensures quality is maintained even during long-distance journeys.

Minimizing Post-Harvest Losses

Post-harvest losses are a major challenge in fruit and vegetable transportation. Studies suggest that up to 30 percent of fresh produce can be lost during transit due to inadequate storage and handling. Refrigerated trucks help minimize these losses by maintaining consistent temperature and humidity levels.

Beyond temperature, proper air circulation is equally important. Controlled airflow prevents moisture buildup, which can cause rot and mold, especially in delicate items like strawberries, grapes, and avocados. Even the transportation of oranges benefits from ventilation systems that prevent condensation, preserving both freshness and shelf appeal.

Investing in fresh produce trucks is all about efficiency and cost savings. Reducing spoilage ensures higher returns for farmers, distributors, and retailers, while also improving customer satisfaction in the fruit and vegetable transportation supply chain.

How Refrigerated Trucks Keep Fruits and Vegetables Fresh

A mobile fresh produce truck is more than just a cold box on wheels. Modern refrigerated trucks are engineered to meet the specific needs of fruit and vegetable transportation, ensuring delicate produce reaches its destination fresh and intact.

Cooling Systems & Airflow

The cooling system is the heart of any fresh produce truck. Advanced systems allow precise temperature control for different types of produce, whether it is banana transport, avocado transportation, or grape transportation.

Uniform airflow is critical. Uneven cooling can create hot spots inside the truck, causing some fruits and vegetables to spoil while others remain fresh. Most fresh produce trucks feature ducted airflow systems that ensure every corner of the cargo area maintains a consistent temperature. This is particularly important for mixed loads, such as trucks carrying both tomatoes and strawberries, which have very different ideal storage conditions.

Some modern systems even offer zone-based temperature control, enabling the simultaneous transportation of different types of produce under optimal conditions. This versatility is essential for distributors handling a wide variety of fruits and vegetables.

Insulation Methods

Insulation is another key factor in maintaining a stable, cold environment inside the truck. High-quality insulated panels reduce heat exchange with the outside, making temperature control more energy-efficient and reliable.

Refrigerated trucks often use materials like polyurethane foam or vacuum-insulated panels to minimize thermal transfer. Insulation also protects sensitive items during loading and unloading, especially in extreme weather. For example, watermelon transportation in summer requires robust insulation to prevent softening, while the best way to transport tomatoes involves protection from temperature fluctuations to avoid cracking or premature ripening.

Proper insulation, combined with advanced cooling and airflow systems, ensures that fresh produce trucks can maintain stable conditions over long distances, even in challenging climates.

For businesses looking for reliable, state-of-the-art solutions in fruit and vegetable transportation, Subzero provides advanced refrigerated trucks designed to preserve freshness, reduce post-harvest losses, and ensure produce reaches retailers and consumers in perfect condition.

Best Practices in Fruit and Vegetable Transportation

Maintaining freshness during fruit and vegetable transportation requires more than just refrigerated trucks. How produce is handled, packaged, and delivered is equally critical. Here are four essential best practices:

- Strategic Route Planning

Efficient route planning ensures that fruits and vegetables reach their destination quickly and safely. For banana transport or the transportation of oranges, minimizing transit time prevents over-ripening and spoilage. Distributors increasingly use GPS-enabled systems to track trucks, avoid delays, and adjust routes in real time, ensuring produce stays at optimal temperatures throughout the journey. - Precise Scheduling

Timing deliveries strategically helps avoid peak traffic, long waits at checkpoints, and unnecessary exposure to heat. Scheduling plays a vital role in vegetables transport and fruit transport, as even minor delays can affect shelf life. By coordinating loading times, transit durations, and delivery windows, businesses can maintain consistent quality for every shipment. - Careful Handling

Proper handling starts with trained staff who understand the delicacy of fresh produce. Grapes, strawberries, and avocados are especially sensitive to pressure and impact, while tomatoes need careful stacking to prevent bruising. Attention during loading, unloading, and in-truck movement reduces the risk of damage and ensures produce arrives in prime condition. - Optimized Packaging

Packaging is about both containment and freshness. Ventilated crates, airflow pallets, and temperature-sensitive liners are widely used in fruit and vegetable transportation. These methods regulate moisture, prevent bruising, and allow airflow, making them essential for strawberry transportation, grape transportation, and the best way to transport bananas.

Conclusion

Fresh produce transportation is a delicate process where every step, from harvest to delivery, affects quality and shelf life. Refrigerated trucks with controlled temperatures, insulation, and uniform airflow are essential to maintain freshness.

Businesses in vegetables transport, fruit transport, and fruit and vegetable transportation must prioritize cold chain integrity. Knowing the best way to transport bananas or tomatoes, along with proper route planning, handling, and packaging, ensures produce reaches stores in optimal condition.

Investing in advanced mobile fresh produce trucks is about efficiency and trust. Subzero’s refrigerated trucks combine technology and expertise, helping businesses deliver superior produce consistently while preserving taste, quality, and nutrition.